Why Do EVs Still Need 12 V Lead-Acid Batteries? Well, They Don’t!

The continuous advancement of lithium-ion battery technology has given electric cars longer driving range, faster acceleration and more horsepower than ever before. And yet, most EVs on the road today still carry around a 12 V lead-acid battery for standby power. But why?

The Legacy of Lead-Acid Batteries

Inexpensive and dependable, lead acid batteries have been around for more than 100 years, including being used in the early versions of electric vehicles back in the 1890s. It offers the high current (500 A in cold conditions for up to 5 seconds) needed to start an internal combustion engine, and the entire electric subsystem of an ICE vehicle has been designed to be powered by the 12 V battery when the engine is turned off.

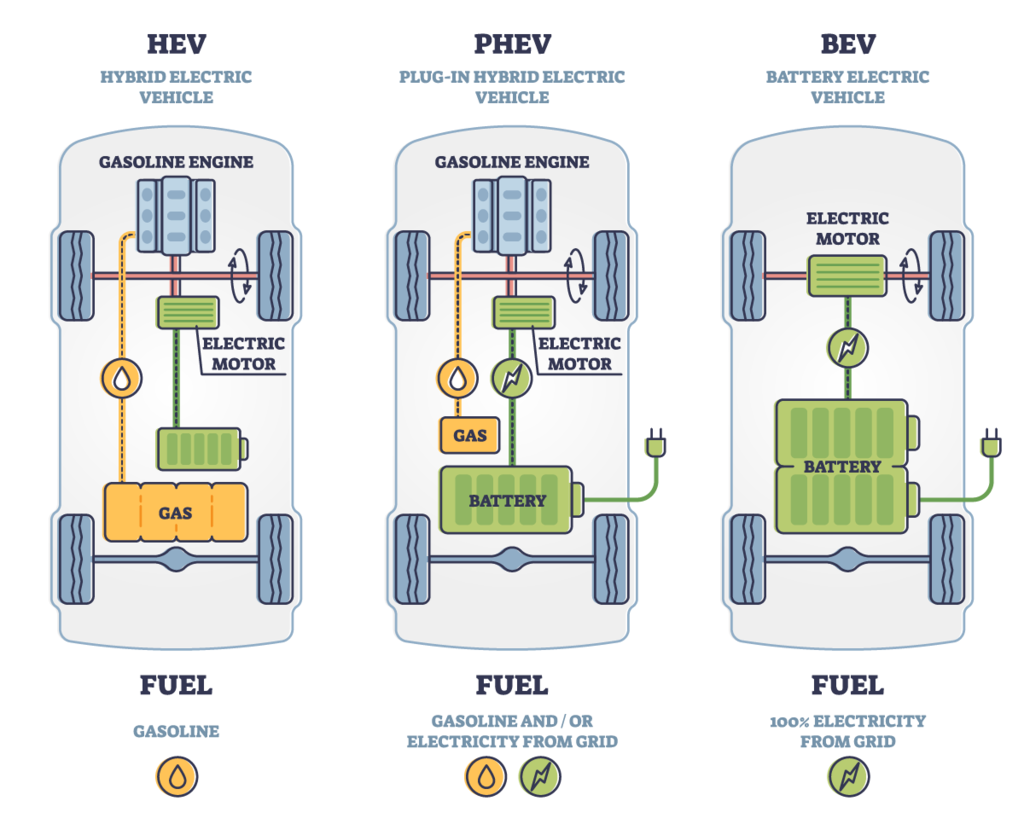

As the auto industry began electrification in the late 1990s with hybrid or plug-in hybrid electric vehicles, a lead-acid battery is still needed because there is still a gasoline engine to be started.

What About Cars Without an Engine?

Even without the need for the 500 A peak output current to start a gas engine, most fully electric vehicles retain the use of this heavy battery for supplying 12 V power to all electric subsystems when the motor is not running. The idea of eliminating the 12 V battery in a fully electric car might sound simple, a few more issues need to be addressed before it can happen:

Cost: Lead-acid batteries are cheap. In most instances, it costs more to employ a DC-DC conversion system to turn 400 V (from the battery pack) to 12 V for all the lights, pumps, windows, power steering and the infotainment/navigation systems.

Complexity: Redesigning anything in a car is complicated work, as automotive qualification alone can take years to complete. Lead-acid batteries offer proven durability and a relatively long lifespan. Designing an electric car to run low-voltage systems with a 12 V battery simplifies engineering.

Safety: Most of the aforementioned low-voltage systems are in very close proximity to the passengers. The idea of them drawing power directly from a 400 V or 800 V battery can be scary. Lead-acid batteries allow the higher voltage to be isolated by disconnecting the main battery back from critical systems. High voltage inside the passenger compartment would require many layers of safety protection. That’s why instead of eliminating the 12 V battery altogether, some recent EV designs opted to replace the lead-acid battery with a much smaller and lighter lithium-based battery with lower available output current.

So What Does It Take to Eliminate the 12 V Battery?

To completely eliminate the 12 V battery requires a rugged power supply that can safely draw from the high-voltage battery packs. It needs to have a wide input voltage range, ideally 30 VDC to 1000 VDC, to cover both 400 V and 800 V nominal battery voltages, as well as 30 V operation for functional safety critical applications.

It needs to be highly efficient to reduce operating temperature and minimize discharge of the traction battery. It also needs to have a low component count, which saves space and increases reliability.

Power Integrations’ AEC-Q100-quaified InnoSwitch3-AQ flyback switcher ICs with a 900 V PowiGaN switch are the ideal solution for such a power supply. The devices use a FluxLink™ feedback link, providing reinforced isolation up to 5000 VRMS for secondary-side control. The circuit will start from 30 V without external circuitry, and the ICs achieve greater than 90% efficiency while consuming less than 15 mW at no-load, which is ideal for reducing self-discharge in battery management systems.

A new design example, DER-953Q, is now available for download on power.com. This compact 100 W power supply uses InnoSwitch3-AQ and eliminates the need for a 12 V battery in electric vehicles. For more information, download RER-953Q Design Example Report and InnoSwitch3-AQ Data Sheet.